15 Jun The Glasses Making Journey

For many, many years, the optometrists at our practice, Eyewise, in Long Lane, have been delivering high standards of care in the eye test room. Most of you are familiar with the question, “Is it better with 1 or 2?”

I could spend a long time talking about the small but essential part of an eye test that I spent 2 years understanding and practising while at university, then spent the next 30 perfecting it!

However, on this occasion, I will divulge a topic that is often not given due importance in conversations that take place when choosing and ordering new eyewear: the journey of making glasses.

What is often not talked about is the very important stage between ordering your glasses and seeing the end product a few weeks later. This is when all the precise measurements, including some facial measurements that are taken at the styling stage, are used to determine the most appropriate lens size for the new glasses. It requires a lot of skill, knowledge, and experience to be able to determine the lens design and size, for this will ultimately affect the look and comfort of the glasses.

Thanks to computer technology, many complicated math problems are taken care of, making the order process a lot easier. The real art is in crafting the lens to fit the frame and then securing the lens without distorting the new frame.

Our (or really “your”) glasses are handcrafted by an independent laboratory based in Watford. Recently, on a trip to the lab to collect some orders, I was given a whistle-stop tour of the whole set-up, where real action takes place. From the moment the orders arrive to the point when they are ready, there are no less than 15 stages of the whole process of making up a pair of glasses.

Some of the main stages are:

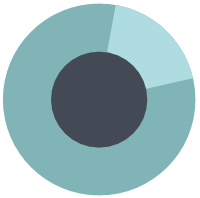

Lens ordering

Ordering the lens blank, such as the one in the photo. The size of the lens blank will depend on where your eyes fall within the frame’s contours. Lens blanks come in a variety of sizes. We need to ensure that the centre of the lens matches the centre of your pupils to maximise the visual performance of the lens. Also, ordering a blank size that is bigger than necessary can result in horribly thick (milk bottle top) lenses. Careful consideration is also made to account for how well the frames wrap around the face, i.e., whether they sit flat or gently wrap in a curved way around the face.

Technology Matters!

Computer-controlled lathe cutting—the fine cutting and shaping of the lens to match the shape of the frame. A lot of heat and debris can be generated, so there is a constant supply of running water to wash away the debris as well as cool down the process. Hand finishing and polishing of the edge of the lens ensures not only a tight, precise fit into the frame but also one that looks aesthetically pleasing.

The Specifics of Colour

For lenses that require a tinting and Ultra-Violet(UV) treatment process, the lenses are then immersed in a tinting bath for a carefully calculated time, to ensure the correct colour and depth of the tint can be achieved. For fashion tints, such as amber, or rose, or blue and blue-green, the process will take longer and will involve repeated checking and calibrating. When demand is high, such as during the summer sunglass season, the process will naturally take longer, especially with custom tints.

It’s not quite Lego, but Lens fitting can be a matter of art!

The lenses, once ready, are mounted into the frame. Most plastic frames need to be gently heated so that the frame can temporarily be stretched in places to house the lens securely. Careful attention is taken to ensure the frames are not overheated. Not all plastic frames are the same- some will take more heat than others to become more malleable. When customers request the re-using of their own frames, this is the stage when sometimes frames crack because they have become too brittle over time. As a general rule of thumb, we would not advise frames that are more than 3 years old, to be used again for the glazing process, due to the inherent risks of the frames breaking, or creating weak areas that may give in the future.

The Set-Up

Once the lenses are secure within the frame, the frames are then set up for the client. The set-up process takes account of the distance to the top of the ear point where the sides bend, to sit gently on the bone structure behind the ears. Some frames will need to be adjusted to account for different ear heights. For people with very small facial features, sometimes the sides need to be trimmed, so that they do not stick out from the back of the ears in an unsightly way. Measurements taken at the frame ordering stage are needed to ensure this part of the process works well(something you cannot achieve with glasses ordered online).

Quality Control

a final inspection is carried out for any flaws or blemishes before the new glasses go through a sanitising and final cleaning process. The complete eyewear is then delicately wrapped in a protective sleeve, ready to be packaged back to our opticians.

A lot of concentration, dedication, and love is imparted between the various stages of making up your glasses, as they are managed by individuals who have their specialties in particular areas of the process.

The lovely dispensing opticians carry out their strict checks before preparing the eyewear for the recipient to collect, continuing this.

A lot of time is often spent before, during, and after the glasses-making process. Despite the advent of technology and automated machinery, nothing beats the essential human touch that goes such a long way to ensure your new glasses will delight you for years to come!

Hopefully, this small account has taken you on an interesting glasses-making journey and provided you with some valuable insight into the deep level of work that takes place behind the scenes at Eyewise!

No Comments